PCM Vulcain™ ultra high temperature pump

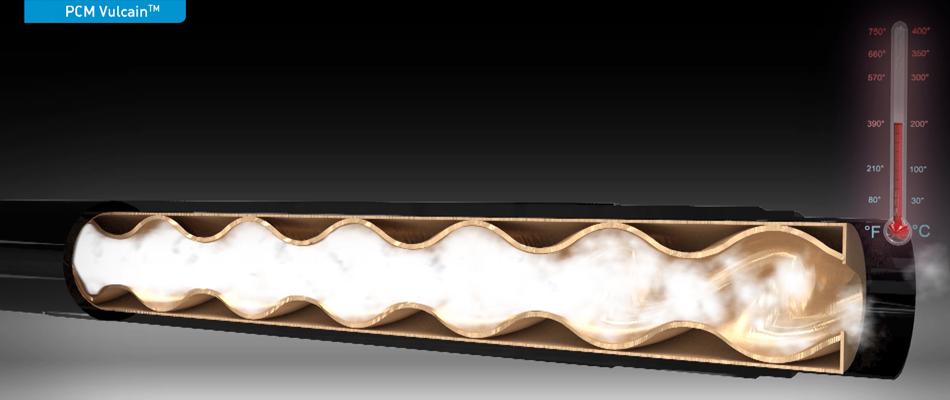

With a PCM unique and patented ultra-high temperature PCP technology, PCM Vulcain™ high temperature oil transfer pump boosts usual PCP temperature limitation up to 350°C/660°F.

With a metal stator replacing the elastomer, the PCM Vulcain™ All- Metal PCP (AMPCP) features the same geometry and advantages as a conventional PCP but with the elimination of elastomer temperature and compatibility limits.

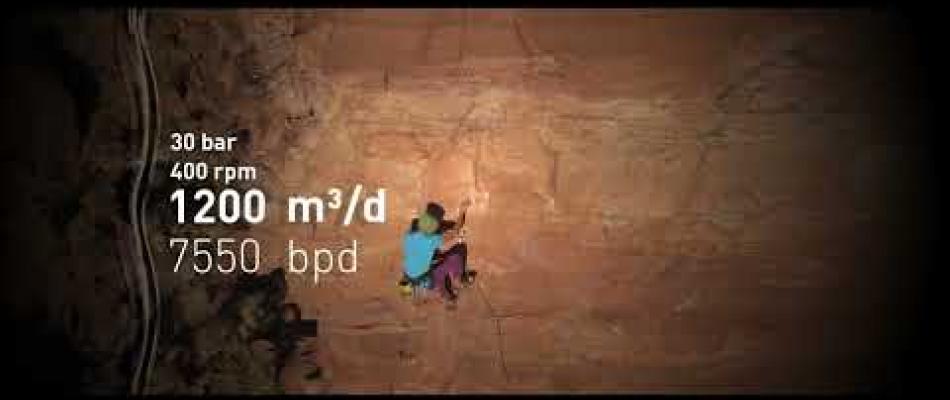

It runs at low intake pressure; keeps good volumetric efficiency (even when pumping 100% water and steam) and can handle very viscous fluid.

These features make the AMPCP technology highly versatile, as it is virtually unaffected by transient periods such as: SAGD warm-up period; beginning or end of the production in CSS; erratic heat front propagation or fluctuation during steam flood production.

| Model | Displacement m3/d/rpm (bpd/rpm) |

Head m (ft) |

Stator OD mm (inch) |

Stator Length m (ft) |

Rotor Connection | Rotor OD mm (inch) |

Rotor Length m (ft) |

|

| PCM VULCAIN™ 3'' 1/2 SERIES | ||||||||

| 45V800 | Download PDF | 0,45 (2,8) | 800 (2620) | 96 (3,78) | 5,78 (19) | 1" API | 51 (2,01) | 6,15 (20,2) |

| 45V1200 | Download PDF | 0,45 (2,8) | 1200 (3940) | 96 (3,78) | 8,58 (28,1) | 1" API | 51 (2,01) | 8,95 (29,4) |

| 45V1600 | Download PDF | 0,45 (2,8) | 1600 (5250) | 96 (3,78) | 11,38 (37,3) | 1⅛" API | 57,5 (2,26) | 11,75 (38,5) |

| Model | Displacement m3/d/rpm (bpd/rpm) |

Head m (ft) |

Stator OD mm (inch) |

Stator Length m (ft) |

Rotor Connection | Rotor OD mm (inch) |

Rotor Length m (ft) |

|

| PCM VULCAIN™ 4'' SERIES | ||||||||

| 80V660 | Download PDF | 0,8 (5) | 660 (2170) | 115 (4,53) | 5,88 (19,3) | 1⅛" API | 57,5 (2,26) | 6,39 (20,11) |

| 80V1000 | Download PDF | 0,8 (5) | 1000 (3280) | 115 (4,53) | 8,96 (29,4) | 1⅛" API | 57,5 (2,26) | 9,30 (30,6) |

| 80V1350 | Download PDF | 0,8 (5) | 1350 (4430) | 115 (4,53) | 11,84 (38,9) | 1⅛" API | 57,5 (2,26) | 12,21 (40) |

| 110V500 | Download PDF | 1,1 (6,9) | 500 (1640) | 115 (4,53) | 5,88 (19,3) | 1⅛" API | 57,5 (2,26) | 6,39 (20,11) |

| 110V750 | Download PDF | 1,1 (6,9) | 750 (2460) | 115 (4,53) | 8,96 (29,4) | 1⅛" API | 57,5 (2,26) | 9,30 (30,6) |

| 110V1000 | Download PDF | 1,1 (6,9) | 1000 (3280) | 115 (4,53) | 11,84 (38,9) | 1⅛" API | 57,5 (2,26) | 12,21 (40) |

| Model | Displacement m3/d/rpm (bpd/rpm) |

Head m (ft) |

Stator OD mm (inch) |

Stator Length m (ft) |

Rotor Connection | Rotor OD mm (inch) |

Rotor Length m (ft) |

|

| PCM VULCAIN™ 4'' 1/2 SERIES | ||||||||

| 220V500 | Download PDF | 2,2 (13,8) | 500 (1640) | 135 (5,31) | 5,91 (19,4) | 1⅛" Mod. API | 72,2 (2,84) | 6,32 (20,8) |

| 220V750 | Download PDF | 2,2 (13,8) | 750 (2460) | 135 (5,31) | 8,8 (28,9) | 1⅛" Mod. API | 72,2 (2,84) | 9,16 (30) |

| 220V1000 | Download PDF | 2,2 (13,8) | 1000 (3280) | 135 (5,31) | 11,58 (38) | 1⅛" Mod. API | 72,2 (2,84) | 12 (39,4) |

| 300V400 | Download PDF | 3 (18,8) | 400 (1310) | 135 (5,31) | 5,91 (19,4) | 1⅛" Mod. API | 73,5 (2,89) | 6,32 (20,8) |

| 300V600 | Download PDF | 3 (18,8) | 600 (1970) | 135 (5,31) | 8,8 (28,9) | 1⅛" Mod. API | 73,5 (2,89) | 9,16 (30) |

| 300V800 | Download PDF | 3 (18,8) | 800 (2620) | 135 (5,31) | 11,58 (38) | 1⅛" Mod. API | 73,5 (2,89) | 12 (39,4) |

| Model | Displacement m3/d/rpm (bpd/rpm) |

Head m (ft) |

Stator OD mm (inch) |

Stator Length m (ft) |

Rotor Connection | Rotor OD mm (inch) |

Rotor Length m (ft) |

|

| PCM VULCAIN™ 5'' 1/2 SERIES | ||||||||

| 400V600 | Download PDF | 4 (25,1) | 600 (1970) | 150 (5,91) | 8,8 (28,9) | 1⅛" Mod. API | 83,4 (3,28) | 9,16 (30) |

| 400V800 | Download PDF | 4 (25,1) | 800 (2620) | 150 (5,91) | 11,64 (38,2) | 1⅛" Mod. API | 83,4 (3,28) | 12,2 (40) |