Select my PCP pumps

Selecting PCP hydraulic (Q & P) is simple but you may need a complete PCP system fine-tuned to your specific application and challenges where details, and experience, can make the difference.

Key point to select:

- PCP Technology (PCP - PCM Moineau™, HRPCP - PCM Slugger, AMPCP - PCM Vulcain™)

- PCP hydraulics Q & P, pitch length and swept angle

- Elastomer type

- Rotor size

- PCP Driving System (Rod Driven, Continuous rod driven, Insert System, PMM, ESPCP)

- Completion accessories (Centralizers, Top tag, Gas Separator, Anti Vibration Sub, Tubing Drain, Torque Anchor, ON/OFF Tools, Paddle rotor, flush Valve…)

- Surface drive equipment

Do it yourself // Quick

Evaluate quickly feasibility of your PCP project; identify PCP model, required rod size and power absorbed.

Do it yourself // Advanced

Based on years of experience worldwide, PCM has developed best practices on PCP completions and operating conditions, according to applications.

Download our PCM Moineau™ operating conditions & completion recommendations

Download our PCM Vulcain™ operating conditions & completion recommendations

PCM has also developed its own PCP selection software, focused on real measurable parameters, proven calculation models and taking advantages of latest technologies and experiences.

Software Key features

Online:

- Stay connected anytime @ anywhere

- Automatic updates to the latest version

Simple:

- Intuitive, easy to understand and simple to use

- Minimized data input time

Expert:

- Optimize and accompany your PCP system throughout its lifecycle

- Ensure the whole system is accurately dimensioned

Not yet registered? Click here to contact PCM to ask for secure and complementary login & password.

Ask a PCM application engineer

You know your wells, we know our PCPs, let us work together to select the best PCP equipment.

Fill in the PCP well datasheet for and get your PCP design from a PCM PCP expert.

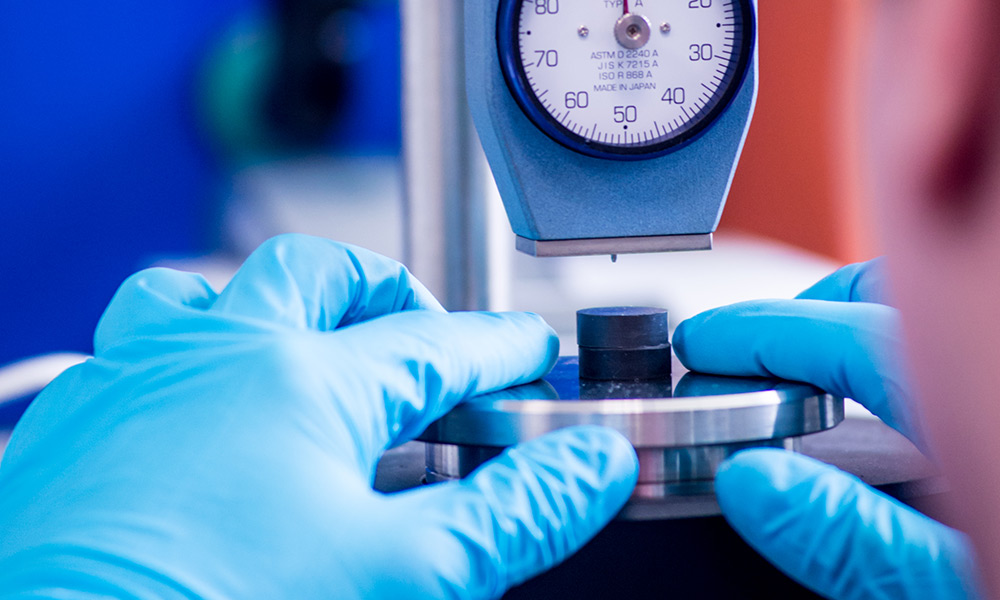

Conduct compatibility test

Elastomer of stator is the heart of PCP. Elastomer is not an inert material and well fluids may affect its geometry (swell, shrink) and/or mechanical properties (softer, harder).

Before running a PCP, conduct a compatibility/swelling test with 3 objectives:

- Confirm Elastomer PCP project feasibility

- Identify the most appropriate elastomer

- Select the best rotor size

All PCM workshop are equipped with laboratory.

Send to the closest PCM workshop:

- 500ml of your fluid sample

- key well data (oil API, BSW, Downhole Temperature, downhole pressure)

PCM will conduct and report swelling tests as per ISO15136-1 standards.

Further information about our elastomers expertise here